Description

Powerbox Core Radio System 8101 Titanium With PBR-9D Receiver

PowerBox-Systems manufactures high-quality RC power distribution equipment, and has now been working for more than two years on its own independent radio control system. On the face of it they may seem a little tardy in introducing a new 2.4 GHz RC system, but upon closer inspection it is precisely this belated entry which gives them one unique advantage:

During the development of this new platform they have not been obliged to make any compromises with regard to compatibility with other systems, and this has enabled them to create new standards in the sphere of 2.4 GHz RC equipment. They placed top priority on the CORE’s security and functional stability. At Nexus we have been using this new Core for many months during its development and love its ease of use and intuitive functionality. Many customers have had the opportunity to try the Core and we have received great feedback.

Radio transmission and power supply

The radio link employs the thoroughly tested frequency-hopping process developed by the Weatronic company. This process is already renowned for its outstanding interference rejection and long range. The CORE’s radio link features integral redundancy, which is monitored by the receiver. For example, if a fault should develop in a transmitting circuit, then the receiver immediately warns the user of this via telemetry. PowerBox is famous for its redundant power supplies, and the CORE’s power system naturally incorporates this: two separate Li-Ion battery units are used, each rated at 3400 mAh / 7.2 V, and the entire power regulation circuit is also duplicated - a feature currently available only in the CORE. The transmitter’s operating time is around ten hours, measured with the screen set to maximum brightness and the system at maximum load.

Telemetry

We believe that telemetry will increase very greatly in importance over the next few years, and the demands made upon it will intensify. For this reason we have invested tremendous effort in developing this aspect of the system. At present there are a few manufacturers of telemetry sensors, and the devices are already in use by many modellers. However, current transmitters’ telemetry systems are either unable to handle a large number of sensor values, or transmission speed is reduced markedly as the number of connected sensors rises. This is the aspect where the strength of the CORE system is most evident:

Telemetry handling and transmission has been the subject of a comprehensive redesign process, with the result that up to 240 sensors can be connected to the P²-BUS, each generating 32 data values, and the system is capable of transmitting up to 800 x 16-bit values per second. For the future this level of performance opens up entirely new possibilities, such as real-time servo monitoring in the model. Our P²-BUS telemetry interface is accessible to third-party manufacturers, which means that customers are not obliged to switch to new sensors for their models; a software update of the sensor system would be sufficient. The configuration and parameter setting procedure for the telemetry system as a whole is conveniently carried out from the transmitter using the radio link.

Linux with smartphone features

The basis of the CORE transmitter is a modern, high-performance Linux PC, which is controlled entirely using the integral touch-screen. The software’s basic look and feel are identical to the typical smartphone. An intuitive user interface provides fast access to all associated settings, with the result that models can be programmed with the minimum of input effort.

Every feature of the user interface has been programmed using Toolkit Qt. Nowadays this development environment is virtually the standard in the sphere of Embedded GUIs, and is employed by many renowned manufacturers.

PowerBox-Systems manufactures high-quality power supply equipment, and has now been working for more than a year on its own independent radio control system. On the face of it we may seem a little tardy in introducing a new 2.4 GHz RC system, but upon closer inspection it is precisely this belated entry which gives us one unique advantage:

During the development of this new platform we have not been obliged to make any compromises with regard to compatibility with other systems, and this has enabled us to create new standards in the sphere of 2.4 GHz RC equipment. We placed top priority on the CORE’s security and functional stability.

Radio transmission and power supply

The radio link employs the thoroughly tested frequency-hopping process developed by the Weatronic company. This process is already renowned for its outstanding interference rejection and long range. The CORE’s radio link features integral redundancy, which is monitored by the receiver. For example, if a fault should develop in a transmitting circuit, then the receiver immediately warns the user of this via telemetry. PowerBox is famous for its redundant power supplies, and the CORE’s power system naturally incorporates this: two separate Li-Ion battery units are used, each rated at 3400 mAh / 7.2 V, and the entire power regulation circuit is also duplicated - a feature currently available only in the CORE. The transmitter’s operating time is around fifteen hours, measured with the screen set to maximum brightness and the system at maximum load.

Telemetry

We believe that telemetry will increase very greatly in importance over the next few years, and the demands made upon it will intensify. For this reason we have invested tremendous effort in developing this aspect of the system. At present there are a few manufacturers of telemetry sensors, and the devices are already in use by many modellers. However, current transmitters’ telemetry systems are either unable to handle a large number of sensor values, or transmission speed is reduced markedly as the number of connected sensors rises. This is the aspect where the strength of the CORE system is most evident:

Telemetry handling and transmission has been the subject of a comprehensive redesign process, with the result that up to 240 sensors can be connected to the P²-BUS, each generating 32 data values, and the system is capable of transmitting up to 800 x 16-bit values per second. For the future this level of performance opens up entirely new possibilities, such as real-time servo monitoring in the model. Our P²-BUS telemetry interface is accessible to third-party manufacturers, which means that customers are not obliged to switch to new sensors for their models; a software update of the sensor system would be sufficient. The configuration and parameter setting procedure for the telemetry system as a whole is conveniently carried out from the transmitter using the radio link.

Linux with smartphone features

The basis of the CORE transmitter is a modern, high-performance Linux PC, which is controlled entirely using the integral touch-screen. The software’s basic look and feel are identical to the typical smartphone. An intuitive user interface provides fast access to all associated settings, with the result that models can be programmed with the minimum of input effort.

Every feature of the user interface has been programmed using Toolkit Qt. Nowadays this development environment is virtually the standard in the sphere of Embedded GUIs, and is employed by many renowned manufacturers.

The transmitter screen is manufactured to the specification of PowerBox-Systems, and is very clearly legible even in bright sunshine. A light touch on the surface of the capacitive touchpad is all that is required. The smartkeys (quick-select buttons) located at the bottom edge of the screen provide instant access to important functions such as Servo Monitor and Screen Lock.

Internal data communication is implemented via the CAN-BUS. This proven bus system is absolutely ideal for our use, and has already been employed successfully in the car and aviation industries for several decades.

Clear evidence of our system’s high-speed processing is found in the Servo Monitor: when the transmitter controls are moved, the screen responds totally in real time! As standard the Linux computer features OpenGL support, which provides almost unlimited scope for graphics, even in the future.

The transmitter screen is manufactured to the specification of PowerBox-Systems, and is very clearly legible even in bright sunshine. A light touch on the surface of the capacitive touchpad is all that is required. The smartkeys (quick-select buttons) located at the bottom edge of the screen provide instant access to important functions such as Servo Monitor and Screen Lock.

Internal data communication is implemented via the CAN-BUS. This proven bus system is absolutely ideal for our use, and has already been employed successfully in the car and aviation industries for several decades.

Clear evidence of our system’s high-speed processing is found in the Servo Monitor: when the transmitter controls are moved, the screen responds totally in real time! As standard the Linux computer features OpenGL support, which provides almost unlimited scope for graphics, even in the future.

Features:

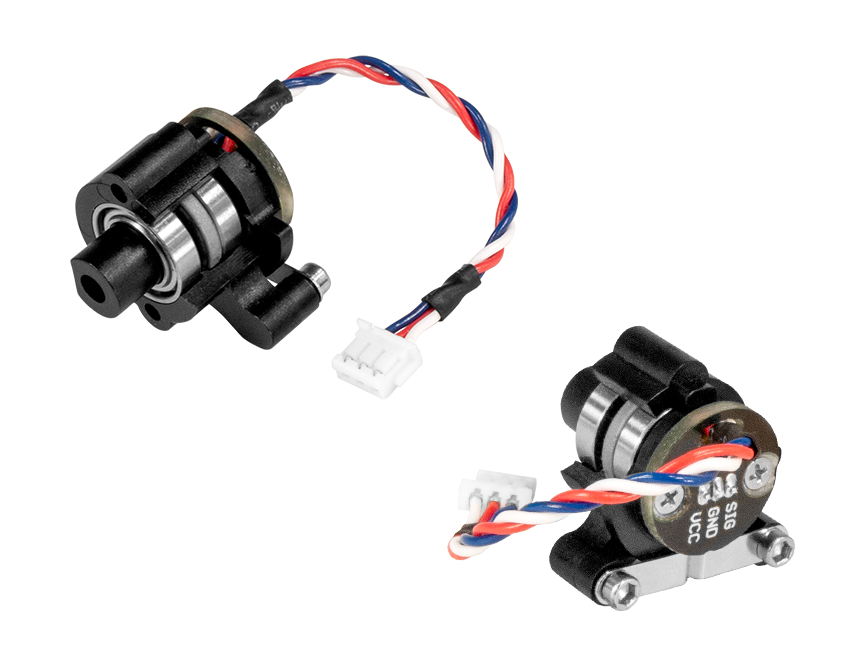

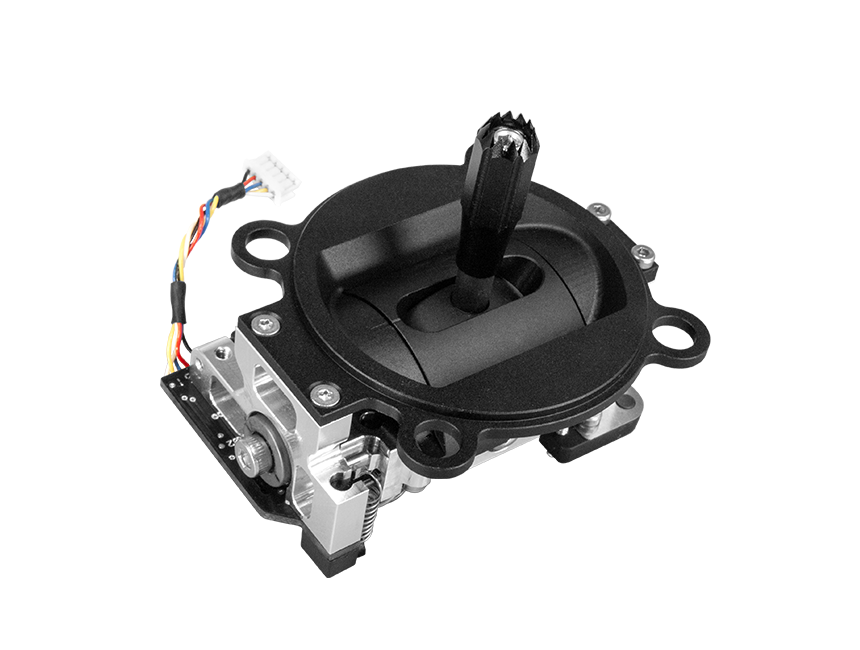

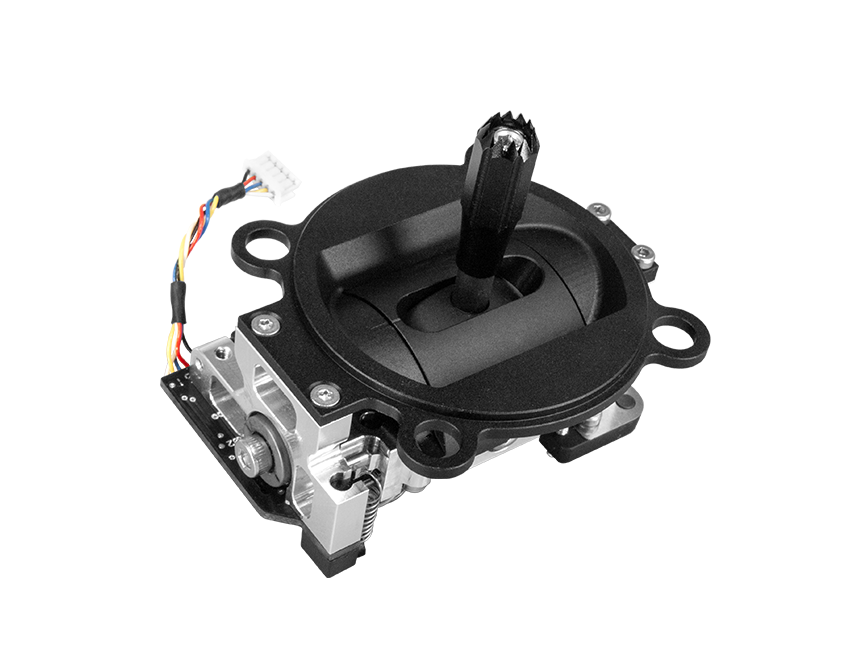

In terms of physical controls the transmitter is fully expanded as standard - with the exception of the stick-switches. If these are required, they can be retro-fitted by the customer himself or by our Service Department; the transmitter’s hardware provides the appropriate sockets. The standard controls are two primary stick units machined from the solid, exploiting Hall sensors with 16-bit resolution and a further four linear controls. These are also based on totally wear-free Hall sensor technology, and each features twin ballraces.

The transmitter is equipped with eight toggle switches, of which the bottom pair are two-position types; all the others are three-position switches. However, this arrangement can be altered at any time by the user; for example, it would be possible to fit latching switches, or switches with different-length toggles. If the customer so desires, potentiometers could even be fitted. The inputs for the transmitter controls are designed to offer maximum flexibility. Another new feature in the overall design is the pair of momentary switches to left and right of the primary sticks: these are the perfect choice for controlling wheel brakes, electric starters or smoke pumps.

A fantastic extra is now available in the Stick Switch. There is the 2- or 3-Position switch or 2- or 3-Position switch with push-button. These are only available to buy with a CORE or Atom. You can not buy these individually and they have to be installed by PowerBox.

Look and feel

When you pick up and hold the CORE transmitter, you immediately feel at home with it: all the switches are laid out in the pattern familiar from other High-End systems. Our aim has always been to give pilots a professional “tool” which they can immediately use to the full. The Alcantara leather hand-hold facings are immediate evidence that this is a very high-grade device. And just as important: the transmitter simply fits perfectly in the hands.

High-speed signal transmission

The CORE provides 26 channels, each with 4096-bit resolution. Despite this, the control data are transmitted using a 10 ms frame rate with zero delay. All channels have full resolution, and there are no limitations to the frame rate.

Further highlights

Special features of the transmitter include integral GPS, a 9-axis motion sensor, USB and a WLAN socket. Amongst other uses, the latter is employed for updating the software for the entire system. Receivers can be updated very conveniently via the radio link, i.e. it is not even necessary to remove them from the model.

The receiver units

Four different receivers are available to match the CORE:

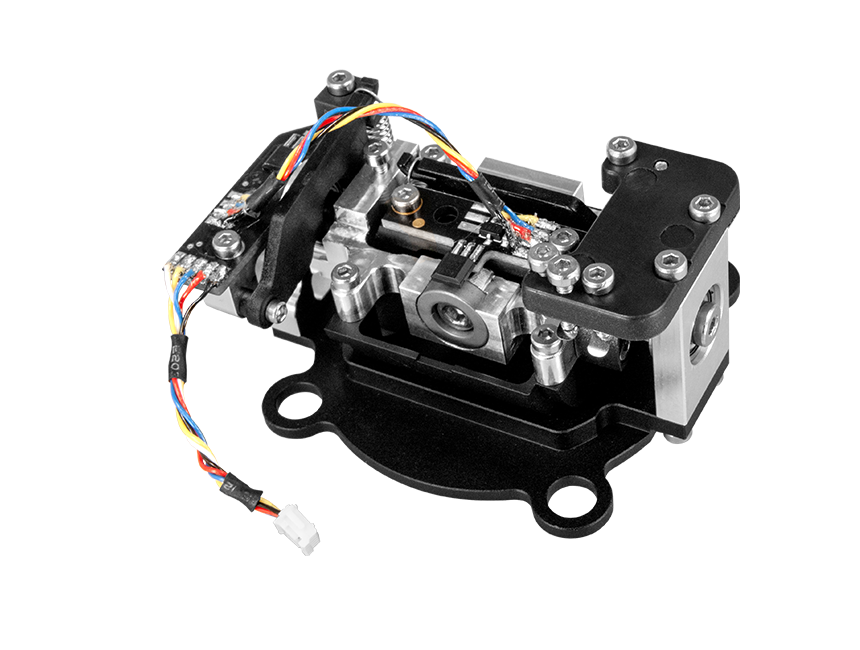

PBR-9D

This is a nine-channel receiver with two redundant receiver circuits. The unit features a P²-BUS interface for servo and telemetry data, and an auxiliary output which can be configured either as SRXL bus or as channel 10.

PBR-7S

This is a seven-channel receiver with a single receiver circuit. The unit features a P²-BUS interface for servo and telemetry data, and an auxiliary output which can be configured either as SRXL bus or as channel 8.

PBR-5S

This is a five-channel receiver with a single receiver circuit and an integral Chip aerial. The unit features a P²-BUS interface for servo and telemetry data, while its minuscule size makes it the natural choice for small models.

PBR-26D

This is a satellite receiver featuring two redundant receiver circuits. The unit features a P²-BUS interface for servo and telemetry data, and an auxiliary output which can be configured either as SRXL bus or S-BUS. This unit is designed to be connected to our PowerBox power supply systems or a flybarless system.

With the exception of the PBR-5S all these receivers are also available with an integral PowerBox iGyro!

Features:

- 26-channel radio control system

- extremely secure against interference, genuine redundant 2.4 GHz transmission

- extremely long range

- redundant PowerBox power supply system

- high-performance real-time telemetry

- up to 800 telemetry values per second

- open bus interface for servos and telemetry

- aluminium stick units

- hall sensors for sticks and slider controls

- 20 transmitter controls + 2 optional stick switches

- full-colour screen with capacitive touch-screen

- high-contrast screen, legible in sunlight

- intuitive menu system with Smartkeys

- integral GPS system

- Linux PC system for every imaginable expansion

Set contents:

- PowerBox CORE

- 1x PBR-9D

- Core Case

- Neck strap

Technical Data:

| Power supply | Li-Ion |

| Channels | 26 |

| Servo signal resolution | 4096 Steps |

| Screen | TFT - Touch |

| Weight | 1152g |

| Temperature range | -30°C to +85°C |

Please note. Some phots are of the pre production Core Transmitter and this is not the final product but we thought it would be good to show pictures from The Jet Power 2017 where the prototype was launched & 2018 where we go to see the version we have today.

Please note that a windows computer is required for the PowerBox updates.